Around the world, industries and farms are under pressure to cut greenhouse gas emissions. High-GWP (Global Warming Potential) gases like methane and nitrous oxide are particularly harmful because their warming effect is much stronger than carbon dioxide. Many people ask: is there a way to turn agricultural waste into something useful while also cutting emissions? The answer lies in modern biochar production machines, which transform waste into value while helping fight climate change.

Modern biochar machines, like those manufactured by DOING Company, use pyrolysis technology, a high-temperature, oxygen-limited environment where biomass is carbonized instead of decomposing or burning uncontrollably. This process locks most of the carbon into the solid biochar, minimizing the generation of high-GWP greenhouse gases, while capturing byproducts such as syngas and wood vinegar for reuse.

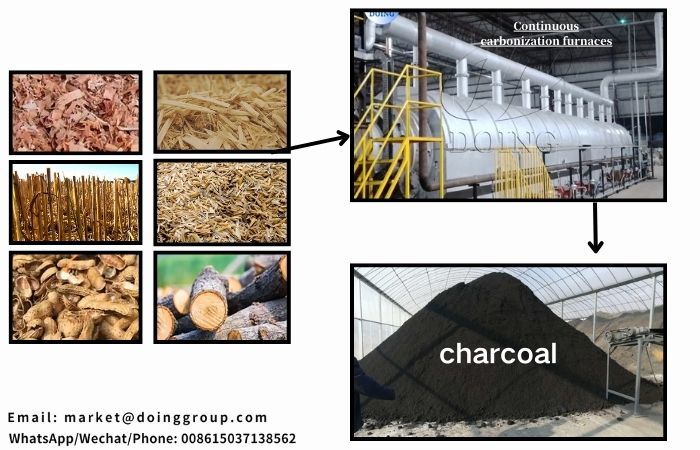

DOING biomass pyrolysis machine for biochar production

DOING biomass pyrolysis machine for biochar production

When crop residues, animal manure, or other biomass are left to rot or burned in the open air, they release large amounts of CO2. However, during biochar production, the carbon in the waste is fixed in the charcoal, avoiding direct CO2 emissions. Furthermore, open-air burning can contribute to smog, health problems, and soil nutrient loss.

Methane and nitrous oxide are two major greenhouse gases produced during agricultural waste processing. These gases have extremely high global warming potentials. Biochar production equipment suppresses these emissions through the pyrolysis process, helping to reduce atmospheric greenhouse gas levels.

Biochar production machine not only effectively reduces greenhouse gas emissions but also converts waste organic matter into usable biochar products. This recycling process reduces waste pollution while providing economically valuable soil conditioners and energy.

Biochar production for emission reduction and biochar resource recycling

Biochar production for emission reduction and biochar resource recycling

By doing so, the machine prevents methane and nitrous oxide emissions that would otherwise escape into the atmosphere. The result is not only reduced greenhouse gas emissions but also the production of valuable resources for farming and energy.

Carbon Sequestration – Biochar can store carbon in the soil for decades or even centuries. This carbon sequestration in the soil further reduces atmospheric carbon concentrations.

Emission Reduction – Biochar production equipment can reduce the burning of agricultural waste and forestry residues, such as wooden blocks, branches, plant bushes, coconut shells, rice bran, straw, nut cores, empty palm fruit skewers, etc., thereby lowering harmful gas concentrations in the air.

Soil Improvement – Biochar can be used to improve soil quality, enhancing water retention, nutrient cycling, and microbial activity, improving agricultural production efficiency.

Energy Recovery – Synthesis gas can be used to heat pyrolysis furnaces, reducing the use of fossil fuels.

At Henan DOING Holdings, we provide batch type, semi-continuous, and fully continuous biochar production machines, allowing customers to select the most suitable system based on raw materials and project scale. Our equipment is designed with advanced sealing, automated controls, and smoke purification systems to ensure high efficiency and minimal emissions.

DOING biochar production machine

DOING biochar production machine

Beyond machines, we offer project consultation, raw material testing, plant layout design, installation, and training. With customers in more than 100 countries, our global service network ensures that you receive support every step of the way.

Biochar production machines are more than just tools for waste treatment — they are a solution to reduce high-GWP greenhouse gas emissions while creating valuable products. By choosing Henan DOING Company, you gain reliable equipment, sustainable technology, and professional support that benefit both your business and the environment.

Please provide us with project information as much as possible.