In biomass carbonization production, charcoal yield is a critical indicator for measuring equipment performance and production efficiency. The level of charcoal yield directly affects production costs and economic benefits, and it is influenced by multiple factors affecting charcoal yield. Below, we analyze the core factors affecting the charcoal yield of biomass carbonization equipment from four dimensions: raw materials, equipment, process, and operation.

Doing biomass carbonization production equipment

Doing biomass carbonization production equipment

Raw Material Characteristics Determine Carbon Yield

The type, moisture content, and pre-treatment level of raw materials significantly impact charcoal production efficiency. Different biomass materials vary in lignin and cellulose content, leading to notable differences in charcoal yield: hardwoods and bamboo, which are high in lignin, can achieve a charcoal yield of 25%-30%, while straw and rice husks, as herbaceous materials, typically yield only 15%-20%. Moisture content is a key parameter—when it exceeds 20%, the carbonization process consumes substantial heat to evaporate water, resulting in insufficient effective carbonization temperatures and incomplete conversion of organic components, reducing charcoal yield by 5%-10%. Additionally, inadequate pre-treatment affects charcoal production efficiency. Large, unprocessed raw materials heat unevenly, leading to incomplete internal carbonization, while impurities like soil and stones absorb heat, lowering efficiency and reducing yield.

Various biomass carbonization raw materials

Various biomass carbonization raw materials

Equipment Performance Directly Affects Charcoal Production Efficiency

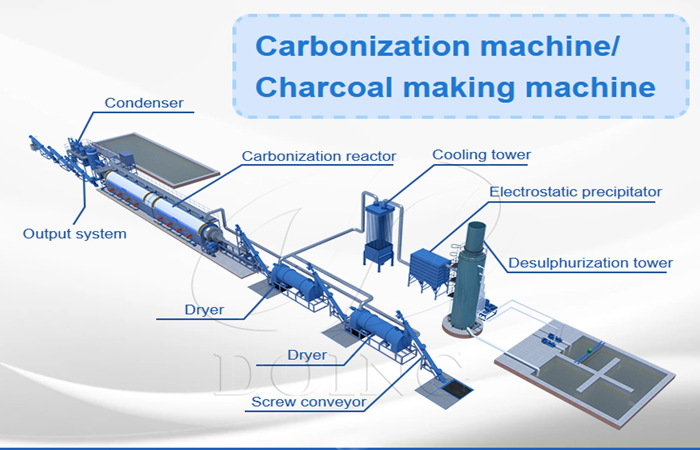

The structural design and core performance of biomass carbonization equipment are crucial for ensuring high charcoal yield. Poorly sealed equipment allows air infiltration, causing oxidation and combustion instead of carbonization, which can reduce yield by over 10%. Insufficient or uneven heating system power results in temperatures below 400°C, leading to incomplete pyrolysis and a significant drop in charcoal yield. HENAN DOING’s continuous carbonization furnace significantly improves charcoal yield with its advanced features: an intelligent temperature control system precisely maintains temperatures between 500-800°C, ensuring thorough carbonization; an even feeding design maximizes heat exposure, minimizing partial uncarbonized material; and an efficient insulation layer reduces heat loss, improving thermal efficiency. Compared to traditional equipment, it increases charcoal yield by 8%-15%,addressing factors affecting charcoal yield.

HENAN DOING's continuous carbonization furnace

HENAN DOING's continuous carbonization furnace

Process Parameters Determine Carbonization Effectiveness

The rationality of carbonization process parameters directly impacts charcoal production efficiency. Improper heating rate control is a common issue—too fast causes rapid surface carbonization, forming a "hard shell" that hinders internal pyrolysis, while too slow prolongs the process, increasing volatile loss, both reducing yield. Matching carbonization time and temperature is critical. Different materials require specific parameters: wood carbonization requires 2-3 hours at 600-700°C, while straw carbonization needs 1-2 hours at around 500°C. Mismatched parameters can cause charcoal yield fluctuations of 5%-20%, highlighting the importance of optimizing factors affecting charcoal yield. Poor pressure control in the furnace can also hinder volatile gas release, inhibiting carbonization and indirectly lowering yield.

Operational Standards Impact Production Stability

Operator skill and adherence to procedures directly influence charcoal yield. Improper feeding - either excessive material causing poor heat distribution or insufficient material leading to energy waste - can reduce yield by 3-8%. Equipment maintenance is equally critical, as issues like ash accumulation or seal degradation gradually diminish performance. DOING addresses these challenges through comprehensive operator training programs accompanying our carbonization systems, ensuring proper operation techniques and maintenance protocols are mastered. Our technical team provides on-site guidance covering optimal feeding practices, temperature regulation, and troubleshooting methods, enabling operators to maximize charcoal yield while maintaining equipment efficiency. This integrated approach of advanced equipment combined with professional training delivers sustained production stability and output quality.

DOING carbonizing machine production service team

DOING carbonizing machine production service team

Charcoal yield is the result of multiple interacting factors affecting charcoal yield, requiring optimization in raw material pre-treatment, biomass carbonization equipment selection, process refinement, and standardized operation. DOING’s continuous carbonization furnace enhances charcoal yield through precise temperature control, uniform heating, and high-efficiency sealing. If you seek to optimize carbonization production and improve charcoal yield, feel free to contact us for customized solutions and equipment support!

Please provide us with project information as much as possible.