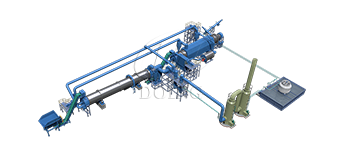

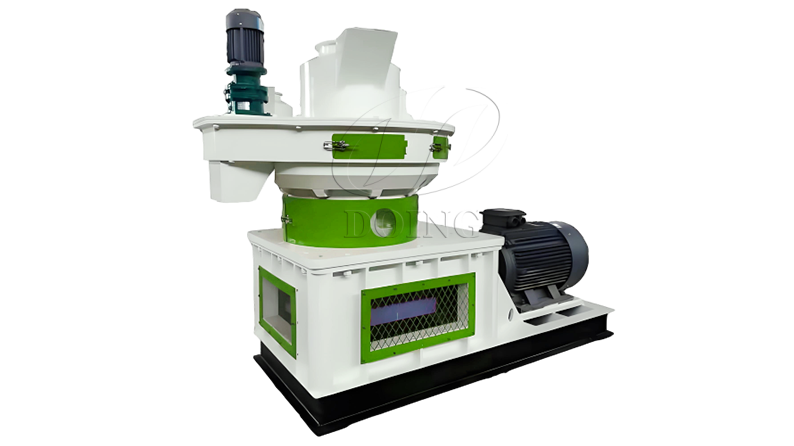

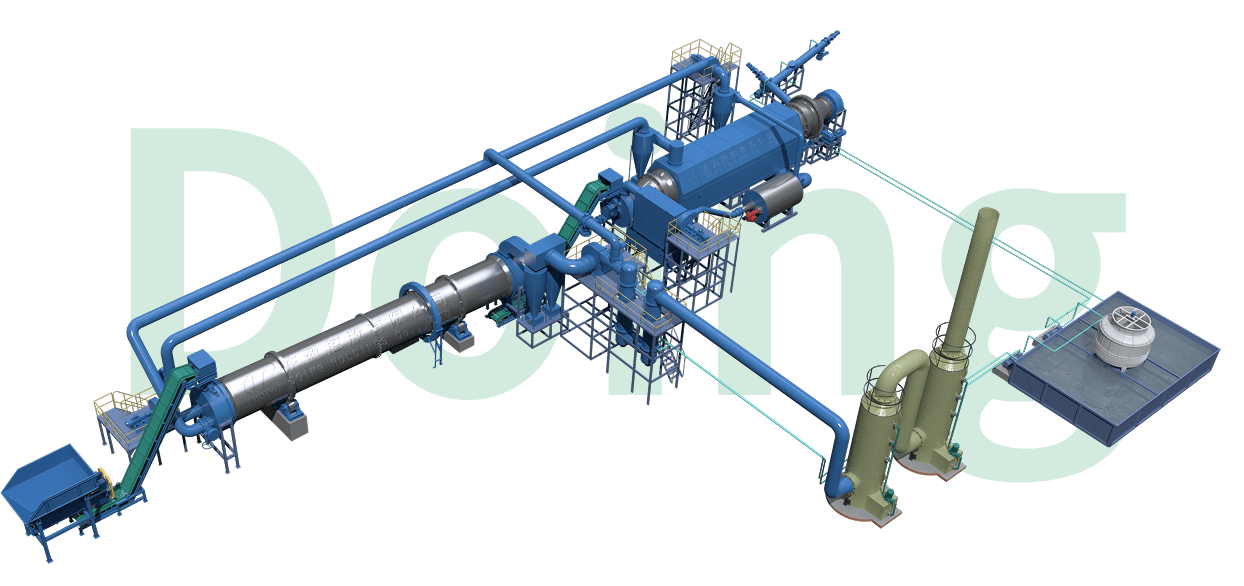

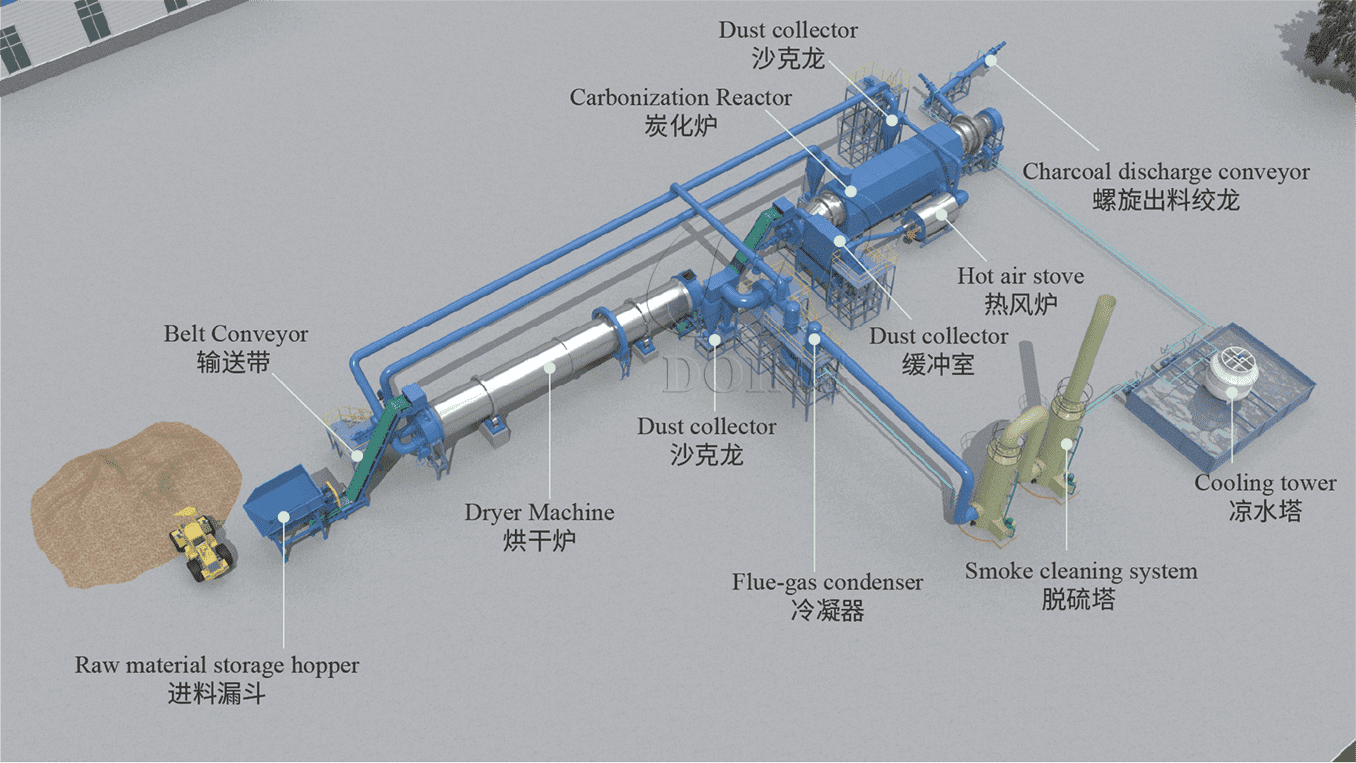

Charcoal making machine utilizes pyrolysis technology to efficiently convert biomass(such as wood, nutshells, corn cobs, rice husks, straw, forestry residues, bamboo, etc.) and various organic wastes in a high-temperature, oxygen-free environment.

Through DOING carbonization machines, biomass waste will be converted into high-value biochar, tar(bio-fuel) and wood vinegar, while also generating syngas and thermal energy, achieving resource circular utilization and creating significant economic and environmen-tal benefits.