For centuries, we've depended on traditional charcoal, whether for fuel or to improve soil. But that dependence comes at a cost. Its production typically means cutting down trees, leading to deforestation, while traditional kilns are inefficient, costly to run, and emit significant carbon. The process itself is slow, energy-heavy, and the resulting charcoal has limited use. We clearly need a smarter alternative—one that’s both sustainable and practical. That alternative is biochar production from agricultural waste. This approach transforms leftover biomass, like crop residues, into a high-value product. It tackles waste, conserves natural resources, and produces a stable, carbon-rich material that supports a true circular economy in farming.

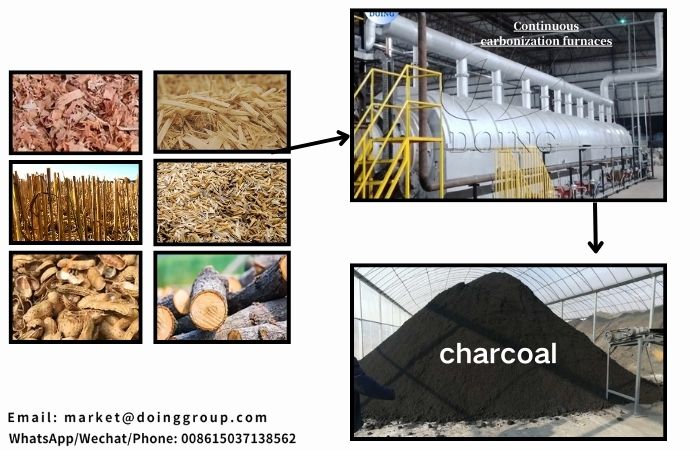

Various agricultural wastes used to produce biochar

Various agricultural wastes used to produce biochar

In the production of biochar from agricultural waste, a wide range of raw materials are available and can be tailored to local conditions. Besides common wastes such as rice husks, coconut shells, and crop straw, many regional byproducts—such as olive pits, coffee shells, bagasse, or palm kernel shells—can also be effectively used as agricultural biomass feedstocks for biochar production. The moisture content and particle size of the biomass feedstock are also important considerations during carbonization. The moisture content should be below 50%; if high, dehydration is necessary to avoid excessive energy consumption during drying. The particle size should be controlled to below 3 cm; larger particles should be crushed to ensure uniform heating and thorough carbonization within the reactor. Properly prepared feedstocks not only produce more stable biochar but also improve the efficiency and durability of equipment designed for biochar production from agricultural waste.

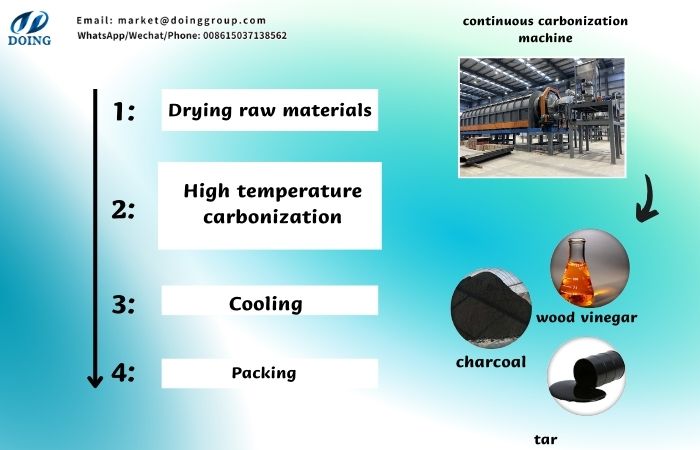

Biomass pyrolysis charcoal production equipment

Biomass pyrolysis charcoal production equipment

The production of modern biochar from agricultural waste revolves around advanced pyrolysis technology. Unlike traditional kiln processes, which are time-consuming, labor-intensive, inefficient, and highly polluting, today's biochar production pyrolysis equipment achieves greater precision, efficiency, and environmental performance through precise temperature control, effective sealing to limit oxygen exposure, durable construction to withstand high-temperature environments, and a high degree of automation supporting stable and scalable biochar production from agricultural waste.

Henan DOING's biochar pyrolysis system is designed with these principles in mind. The carbonization reactor maintains a narrow temperature range of ±5°C, promoting uniform carbonization and preventing over- or under-processing. Its sealed design minimizes air ingress, helping to reduce oxidation and heat loss, thus lowering energy consumption. The equipment is constructed with high-temperature alloys and insulating materials, maintaining durability and excellent insulation even under continuous operation. The process is also highly automated, requiring minimal human intervention for feeding, temperature control, and discharge—making operation more stable, especially in large-scale biochar production from agricultural waste environments.

DOING continuous agricultural biochar pyrolysis systems

DOING continuous agricultural biochar pyrolysis systems

When producing biochar from agricultural waste, the choice of appropriate production equipment depends on your scale of operation and objectives. DOING offers both batch and continuous agricultural biochar pyrolysis systems. Batch biochar production equipment is suitable for smaller plants with lower throughput. For large-scale, industrial-scale biochar production from agricultural waste, continuous carbonization reactors offer significant economic advantages. Their design allows for uninterrupted feeding and discharging, enabling high throughput of 1-5 tons per hour. Compared to batch pyrolysis systems, this significantly increases annual output and efficiency while reducing investment and operating costs per unit of biochar. Furthermore, the sealed structure integrates flue gas purification and combustible gas recovery systems, enabling internal heat circulation. This drastically reduces external fuel requirements, lowers energy costs, and improves the overall profitability of the project, making the sustainable biochar production from agricultural waste a truly economical undertaking.

DOING provide biochar production equipment with a wide processing capacity range, from 100 kg to 50 tons per day. Pricing is tailored to your specific required capacity and configuration. We also offer customized solutions to meet your unique production targets and raw material characteristics. To explore how to efficiently transform your local agricultural biomass feedstock for biochar production into a valuable resource, feel free to contact us for a detailed consultation.

Please provide us with project information as much as possible.