As an environmentally friendly fuel, biomass charcoal offers numerous advantages over traditional natural wood charcoal. The differences and properties between biomass charcoal and natural wood charcoal are reflected in the following four aspects:

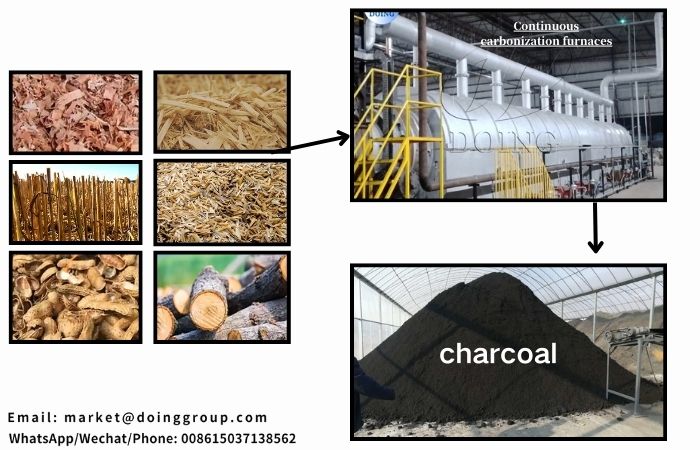

Biomass charcoal is a solid product produced by pyrolyzing biomass materials such as agricultural waste and forestry byproducts under anoxic conditions through carbonization technology. Biochar can be sourced from a wide range of waste materials, including wood, rice husks, straw, fruit shells, and bamboo, effectively utilizing resources by transforming waste into valuable resources.. This production method not only reduces waste accumulation but also avoids the environmental pollution caused by direct incineration. In contrast, the production of natural charcoal typically requires felling trees, which in the long term damages forest resources and the ecological environment.

Biomass carbonization to charcoal technology

Biomass carbonization to charcoal technology

In terms of combustion efficiency, biomass charcoal exhibits stable performance characteristics. Its fixed carbon content remains around 80%, and its calorific value ranges from 7,500 to 8,000 kcal/kg, providing a continuous and stable heat output. Natural wood charcoal, on the other hand, has a relatively low fixed carbon content, with a calorific value of approximately 6,500 kcal/kg.

Biomass charcoal offers several practical advantages during use:

1. It produces virtually no smoke or sparks during combustion, ensuring a cleaner operating environment.

2. Residual ash from the combustion process falls naturally, preventing floating and causing secondary pollution.

3. It has a low ash content, approximately 3%-6%, making it relatively easy to clean and maintain.

4. Its shape and size are standardized for uniformity, and its porous structure facilitates air circulation, sufficient combustion and use.

Regarding storage and usage conditions, biomass charcoal has a low moisture content, typically below 5%. This property facilitates long-term storage and maintains stable combustion performance. Natural wood charcoal, on the other hand, often has a higher moisture content, which can affect combustion efficiency and increase storage difficulties. Furthermore, biochar is non-toxic and odorless, as no chemicals are added during production. It is pollution-free during use, releases no harmful substances, and has a long burning time.

After comparing the differences, we can see that the comprehensive performance of biochar made by biomass carbonization pyrolysis process is better than that of natural charcoal.

To help customers produce high-quality biomass charcoal, DOING offers efficient carbonization machine of varying sizes, suitable for carbonizing a variety of biomass feedstocks. These equipment offers the following key advantages:

1. High Efficiency: Our equipment utilizes advanced carbonization technology to efficiently convert organic waste into charcoal, gas, and liquid products. Through optimal temperature and pressure control, the equipment completes the carbonization process in a short time, maximizing energy utilization and conversion rates.

Products of biomass carbonization machine

Products of biomass carbonization machine

2. Energy Saving and Environmental Protection: The carbonization machine utilizes a closed-loop design, allowing the combustible gases generated during the carbonization process to be recycled and reused as a heat source, reducing energy consumption. Furthermore, during the carbonization process, exhaust gases are purified and treated through an emission control device to ensure compliance with environmental standards, effectively reducing environmental pollution.

3. Wide Range of Feedstock Compatibility: This machine is compatible with a wide range of biomass feedstocks, including agricultural waste (straw, rice husks), forestry residues (wood chips, branches), animal manure, and organic waste. It can effectively process a wide range of waste, providing more options for your biochar production.

Carbonized raw materials for biomass charcoal production

Carbonized raw materials for biomass charcoal production

4. Easy Operation and High Level of Automation: DOING biomass carbonization machine is equipped with an intelligent control system that enables intelligent monitoring and automated operation, significantly reducing labor costs and operational complexity. Furthermore, the equipment has strong adaptability, adjusting operating parameters based on the characteristics of different feedstocks to ensure a stable and efficient carbonization process.

If you are considering the production or use of biomass charcoal, or would like to learn more about carbonization machine, please contact us via our website. Our technical team is always ready to provide detailed consultation and customized solutions.

Please provide us with project information as much as possible.