For many entrepreneurs, investing in a biomass pyrolysis plant represents an attractive opportunity to generate profit by converting abundant agricultural or forestry waste—like wood chips, rice husks, and coconut shells—into valuable products such as biochar, wood vinegar, and syngas. When considering investment in a biomass pyrolysis plant, one of the first questions is often about land required for biomass pyrolysis plant. Many potential investors imagine that such a facility needs a very large area, but in reality, modern biomass pyrolysis equipment is compact and efficient.

Modern biomass pyrolysis equipment

Modern biomass pyrolysis equipment

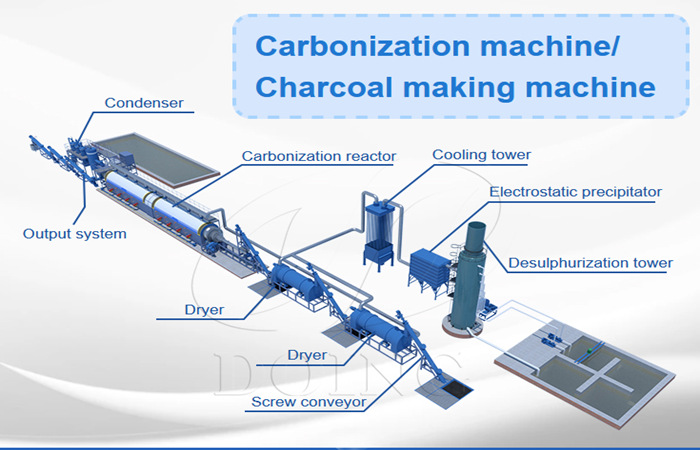

The design concept of modern biomass pyrolysis equipment emphasizes functional integration and space optimization. For example, Henan DOING's biomass pyrolysis equipment system integrates the entire pyrolysis process—feeding, carbonization, cooling, emission, and waste gas treatment—into a compact, continuous flow system. Operation is largely automated, including feeding, parameter adjustment, and product collection. It also incorporates flue gas treatment and combustible gas recovery functions, balancing environmental requirements with operational economics.

Thanks to this integrated design, the actual footprint of the entire core equipment—including the biomass pyrolysis carbonization stove, condenser, cooling system, and necessary auxiliary units—is often more compact than anticipated. Typically, the core operating area of a complete biomass pyrolysis carbonization system can be arranged within approximately 500 square meters. This footprint is achievable for most production sites and provides the possibility of undertaking projects within limited spaces.

Area for storing biochar raw materials

Area for storing biochar raw materials

In addition to the biomass pyrolysis equipment area, it is recommended to prepare extra space for raw material storage and finished products. For example, biomass feedstock such as wood chips, rice husks, or shells should be stored under dry conditions, while biochar, wood vinegar, and syngas collection systems may also need dedicated areas. Depending on the production scale, the total land required for biomass pyrolysis plant can range between 800–1,500 m², which is still relatively small compared to other industrial plants.

The compact design of biomass pyrolysis systems not only reduces land and labor costs but also improves management and production efficiency. DOING's continuous biomass pyrolysis equipment utilizes advanced automation technology and is equipped with a PLC-based control system, allowing operators to remotely monitor and adjust equipment performance. Start-up/stop functions and parameter changes are simple to operate, reducing operational complexity and manpower requirements. The entire continuous biochar production line can be managed by only 2-3 people.

Continuous biochar production line equipped with PLC

Continuous biochar production line equipped with PLC

Starting a biomass pyrolysis plant does not demand extensive land. The core biochar production machine can operate effectively within approximately 500 m². When including storage and handling areas, a total land required for biomass pyrolysis plant of around 1,000 m² is often sufficient. This flexibility makes pyrolysis a practical and scalable investment.

If you are planning a project and would like detailed layout advice or a quotation tailored to your available space and output goals, please feel free to contact us. We are here to help you design an efficient and productive biomass to biochar pyrolysis plant.

Please provide us with project information as much as possible.