When charcoal production is mentioned, images of smoke, deforestation, and environmental pollution often come to mind, prompting many customers to pay attention to the ecological impact of its production process. In fact, whether charcoal production is environmentally friendly depends entirely on the production method used. Traditional charcoal production methods are often accompanied by resource waste and exhaust emissions, while modern biochar production technology has completely changed this situation. Through advanced biochar production equipment, today's biochar production is not only clean and efficient but can even have a positive impact on the environment, truly enabling environmentally friendly charcoal making.

Problems of Traditional Charcoal Production

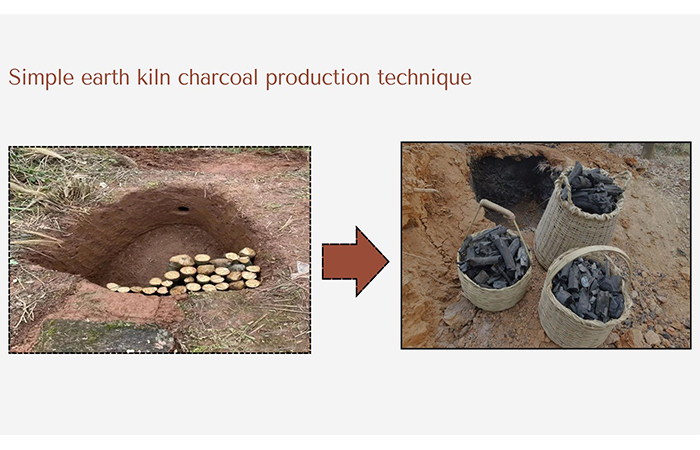

For centuries, charcoal has been produced in simple earthen kilns or pit carbonization stove. This method requires large amounts of wood, burns unevenly, and releases smoke and harmful gases. Forest resources are rapidly depleted, and the process also causes air pollution. In many areas, traditional charcoal production remains a worrying environmental problem.

Traditional charcoal production

Traditional charcoal production

Modern Biochar Production Technology

Unlike the wood-intensive past, modern biochar production technology enables biochar to be made from a wide range of biomass, including agricultural waste like rice husks, coconut shells, and straw, as well as bamboo and even sludge. This not only prevents deforestation but also turns potential waste into a valuable resource. The resulting biochar itself is a multi-beneficial product; when applied to soil, it sequesters carbon for decades, improves water retention, and reduces the need for chemical fertilizers, creating a positive environmental cycle. Beyond soil enhancement, the high-quality biochar produced can also be directed to higher-value markets such as steel manufacturing, barbecue fuel, or even as a raw material for carbon credits, creating diversified revenue streams and significantly improving project profitability.

Carbonization final products and applications

Carbonization final products and applications

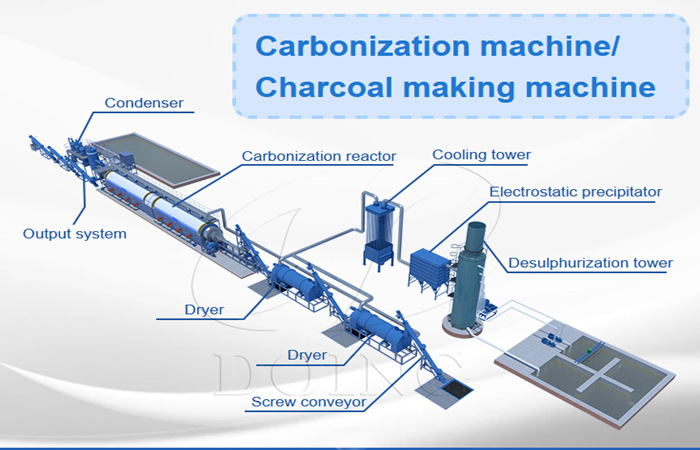

This transformation is made possible by advanced biomass pyrolysis technology, precisely the kind engineered into the biochar production equipment from Henan Doing Holdings Co., Ltd. Our biochar production equipment operate in a sealed, oxygen-limited environment at high temperatures, ensuring that biomass is carbonized through a controlled pyrolysis process rather than open burning. This design effectively contains and purifies smoke, minimizing harmful emissions, making it a model of environmentally friendly charcoal making. Furthermore, the process is engineered for energy efficiency—the combustible syngas produced is typically recycled to fuel the system itself, significantly reducing external energy requirements. This self-sustaining energy model drastically cuts operational costs, making the production process not only environmentally sound but also economically advantageous with a faster return on investment. Meanwhile, other by-products like wood vinegar can be collected for agricultural use, making the entire production process nearly waste-free, environmentally sound, and economically advantageous.

DOING biochar production equipment

DOING biochar production equipment

Henan Doing Holdings offers a comprehensive range of carbonization solutions—including batch-type, semi-continuous, and fully continuous systems—designed to efficiently convert diverse biomass such as agricultural residues and forestry by-products into high-quality biochar. Our biochar production equipment combines robust construction with intelligent design to ensure exceptional energy efficiency, minimal emissions, and operational reliability, helping clients in over 100 countries turn waste streams into value streams while supporting both environmental goals and economic returns. Beyond high-performance machinery, we provide end-to-end services—from technical consultation and customized project planning to biochar pyrolysis equipment installation and operational training—to deliver integrated solutions that establish sustainable production lines, enhance long-term biochar production profitability, and contribute to reducing carbon footprint and building circular economies.

DOING charcoal making machine engineer service team

DOING charcoal making machine engineer service team

Modern biochar production technology has shifted from outdated and polluting practices to innovative and circular solutions compared to traditional charcoal production. It is a technology that actively cleanses the environment by repurposing waste and sequestering carbon, making environmentally friendly charcoal making a reality. With Henan Doing Holdings as your partner, you gain more than just biochar production equipment; you gain a strategic ally in building a profitable, sustainable, and positive-impact enterprise for the future.

Please provide us with project information as much as possible.