Under the global push for sustainable biomass energy utilization, the efficient conversion of organic materials into valuable charcoal has become a key focus. The continuous charcoal production process offers a versatile solution for transforming a wide range of biomass into high-quality charcoal. This comprehensive approach utilizes advanced continuous carbonization furnaces, significantly improving production efficiency, product uniformity, and environmental compliance compared to traditional batch methods.

As a professional manufacturer of continuous carbonization furnaces, DOING provides a detailed breakdown of the entire process:

1. Raw Materials Collection: Diverse Choice for Charcoal Production

Here Henan Doing Company Common lists many kinds of biomass feedstocks for continuous charcoal production:

Wood (logs, branches, wood chips, sawdust) — best overall for high-density charcoal and briquettes.

Corn cobs — agricultural residue with good fixed-carbon content after processing.

Rice husks and rice straw — abundant in rice-growing regions; may need ash-handling strategies.

Coconut shells — high calorific value and dense charcoal output.

Bamboo — fast-growing source producing uniform charcoal.

Peanut shells, nut shells, and fruit stones — small-scale or blended feedstocks.

Biomass mixtures — many plants mix materials (e.g., wood chips + sawdust) for stability and economy.

Carbonized raw materials and carbonized products

Carbonized raw materials and carbonized products

2.Pre-Treatment: Laying the Foundation for Carbonization

Before carbonization begins, raw materials like wood must undergo proper pre-treatment to ensure optimal efficiency. This typically involves:

Crushing: Large pieces of wood are broken down into smaller, uniform sizes, often less than 15mm, which allows for more consistent heating and better carbonization results.

Pellet: If the raw materials are powdery, scatterable sawdust, we usually press them into pellets and process them into biomass pellets.

Drying: The crushed wood is dried to reduce moisture content to below 15%. This step is crucial as high moisture levels can impede the carbonization process and result in low-quality charcoal.

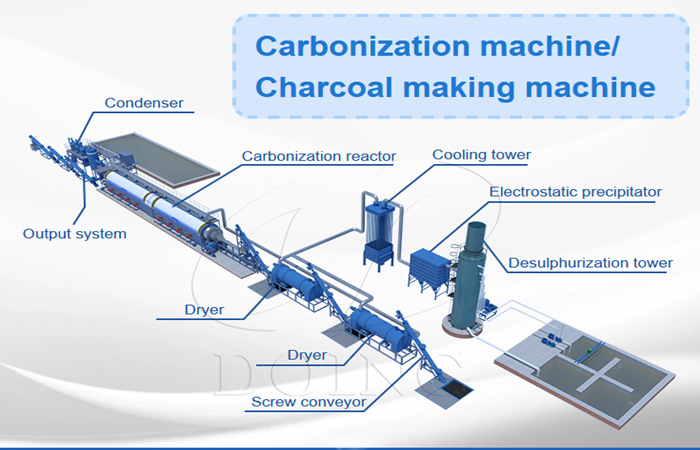

3.Carbonization : Continuous Carbonization Furnace for Efficient Production

Carbonization is the most critical stage in the charcoal production process. Using a continuous carbonization furnace, raw materials undergo pyrolysis at high temperatures. The furnace is designed for continuous feeding and discharging, which eliminates downtime between cycles.

Automated Feeding: Raw materials are fed continuously into the furnace, maintaining a steady and efficient flow of production.

Temperature Control: Advanced continuous carbonization furnaces are equipped with intelligent temperature control systems that regulate the heat in stages. This ensures uniform and complete carbonization of materials. For biomass materials, typical carbonization temperatures are 400–700°C, depending on desired charcoal properties.

Rotary Drum Design: The furnace’s rotary drum ensures that raw materials are evenly distributed and thoroughly carbonized.

The continuous carbonization process eliminates many of the inefficiencies found in traditional batch carbonization methods, offering improved yield, consistency, and energy efficiency.

DOING fullly continuous carbonization furnace

DOING fullly continuous carbonization furnace

4. Cooling & secondary processing: Strict Control for Quality Assurance

Freshly carbonized charcoal is extremely hot and must be cooled quickly to prevent oxidation upon contact with air. The continuous carbonization furnace employs a water circulation cooling system, rapidly reducing charcoal temperature to below 40°C—far more efficient than natural cooling—and effectively preventing spontaneous combustion. This is far more effective and safer than natural cooling, ensuring that the charcoal retains its quality and is safe for handling and storage.

Shaping & briquetting (optional): Charcoal fines can be compressed into briquettes/pellets/sticks by charcoal briquettes extruder machines for uniform fuel or activated-carbon feedstock.

Understanding the continuous charcoal production process is the first step towards investing in a sustainable and profitable venture. DOING’s continuous carbonization furnace represents the forefront of the biomass to biochar conversation technology, offering low energy consumption, high output, and intelligent automation. We provide customized solutions to meet your specific needs, whether you are looking to produce wood charcoal, bamboo charcoal, or charcoal from other biomass materials.

DOING carbonization equipment service team

DOING carbonization equipment service team

If you’re interestedin detailed equipment parameters, investment costs, ROI analysis, or a tailored production plan, feel free to contact us now! Our expert team will provide one-on-one support, helping you seize opportunities in the biomass energy sector while achieving sustainable production and economic success with advanced continuous carbonization furnace technology.

Please provide us with project information as much as possible.