High-quality charcoal generally features a high fixed carbon content, low moisture content, stable combustion, and is smokeless and odorless. Whether used for barbecues, industrial smelting, or daily life, choosing good charcoal not only impacts combustion performance but also directly determines the user experience and benefits.

Stable charcoal quality comes from high-quality raw materials. Commonly used wood materials include hardwoods (such as oak and walnut), bamboo, or agricultural waste (such as fruit shells and straw). The choice of raw materials directly affects the burn time, calorific value, and appearance of the finished charcoal.

Raw materials for good charcoal production

Raw materials for good charcoal production

Recommendation: Ensure that the raw materials are pure, dry, and uniform in size. According to the biomass processing requirements, crushers, granulators and drying furnaces can be used to pre-process the raw materials and help unify the specifications. Avoid using raw materials that have been exposed to chemical or environmental contamination to prevent the production of harmful substances and affect the purity of the charcoal.

Carbonization is the core step in converting biomass raw materials into charcoal through pyrolysis in a high-temperature, oxygen-deficient environment. Precise control of this process is crucial for obtaining high-quality charcoal. By controlling factors such as carbonization temperature and time, uniform carbonization and optimal temperature are achieved, thereby ensuring charcoal quality and improving carbonization efficiency.

Controlling factors of charcoal carbonization process

Controlling factors of charcoal carbonization process

Temperature Control: Too low a temperature may not completely remove harmful substances, affecting charcoal quality. Too high a temperature may increase ash content, reduce yield, and make the charcoal brittle. Furthermore, different raw materials have their own suitable carbonization temperature ranges.

Carbonization Time: The carbonization time determines the length of time the raw materials remain in the furnace, which, along with the temperature, influences charcoal quality. Too short a time results in incomplete carbonization, resulting in a high content of undecomposed substances in the product. Too long a time may result in an overly loose structure, reducing its strength and density.

Oxygen Management: A strict oxygen-deficient environment is essential for ensuring thorough carbonization rather than direct combustion. This environment helps control oxidation reactions and reduce byproduct formation, ultimately yielding good charcoal. Therefore, selecting carbonization with good sealing properties effectively isolates excess oxygen, ensuring production safety and consistent product quality.

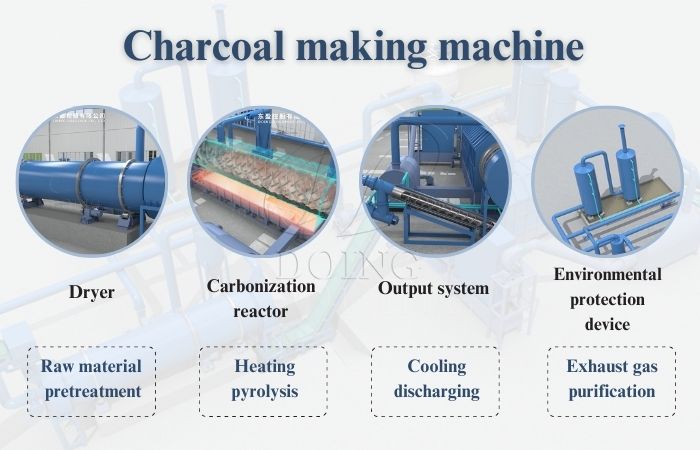

When selecting carbonization machine, factors such as sealing, heating temperature uniformity, and flue gas purification must be considered to ensure a smooth carbonization process. DOING carbonization machine features an intelligent design that integrates biomass raw material pretreatment, automated loading, drying, carbonization, and cooling systems, as well as the back-end charcoal briquette and rod extrusion equipment, minimizing human interference, improving charcoal yield, and maintaining consistent quality from batch to batch.

DOING carbonization machine for high quality charcoal production

DOING carbonization machine for high quality charcoal production

Our charcoal production line design prioritizes tightness and thermal efficiency. A PLC control system allows producers to more precisely control the temperature and duration of the carbonization process, ensuring even heat distribution and fully carbonizing the various raw materials at high temperatures, resulting in purer, denser charcoal. Furthermore, our carbonization machine design incorporates flue gas treatment, contributing to a more environmentally friendly production method.

After carbonization, the cooling process should be slow and airtight to prevent the charcoal from spontaneous combustion due to rapid cooling. After complete cooling, the charcoal should be screened to remove impurities before packaging. It should be stored in a dry and ventilated environment to prevent moisture absorption and affect combustion. If there are requirements for the appearance of charcoal, you can also use charcoal rod making machines, briquetting machines, etc. to plasticize the charcoal to produce spherical, rod-shaped, block-shaped charcoal, etc.

Producing good charcoal requires a comprehensive coordination of raw materials, processes, and equipment. Selecting the right modern charcoal production machine is a key step towards efficient, environmentally friendly, and consistent production. If you are looking for solutions to improve charcoal quality and production efficiency, or would like to learn more about our charcoal making machine, please feel free to contact us.

Please provide us with project information as much as possible.